For many years, GE has been an industry leader in turbine technology and innovation. Today, Dabonn Turbines continue to lead the way, delivering efficiency and reliability that help ensure the success of our customers.

Dabonn steam turbines equip 41% of the world's combined-cycle plants. Right now there are more than 1,000 combined-cycle steam turbines operating in 70+ countries, generating more than 140 GW of power. Our steam turbines can be installed and operational in eight months or less for industry-leading commissioning.

Welded rotors

Single bearing design

Advanced sealing features

High-efficiency last-stage blades

Advanced blading

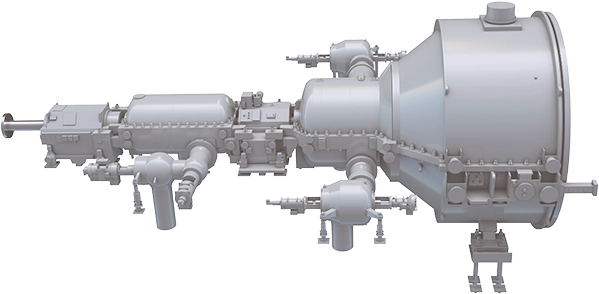

Whatever the requirement, we supply OEMs with either bare metal steam turbine drives or complete packages including gears, lubrication systems and controls. Dabonn steam turbines include standard single-stage turbines conforming to API 611 General Purpose (GP) standards for pump, fan and small compressor drives, standard and engineered single-stage turbines as generator drives for waste heat recovery applications, and engineered single-stage turbines and Standard multi-stage turbine for applications complying with API 611 (GP) or API 612 (Special Purpose - SP) standards. Its power output ranges from 10kW to 25MW. Inlet steam pressure is 30 to 139 bar(a) and inlet steam temperature is 415 to 550 °C.

We are a dedicated steam turbine service provider with regional service teams to support your local steam turbine maintenance needs. Our support includes OEM technical expertise for single-stage, multi-stage and engineered multi-stage steam turbines. Our operating network consists of world-class factories, service centers, supplier networks and warehousing logistics and inventory centers.

Explore our turbine portfolio:

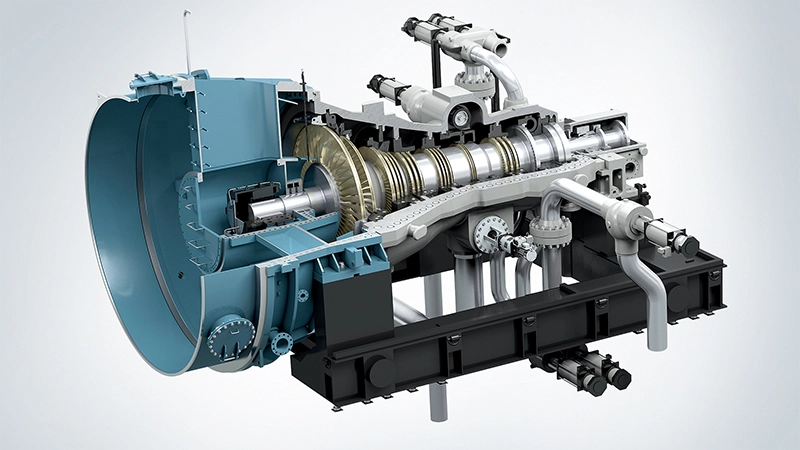

SST-800

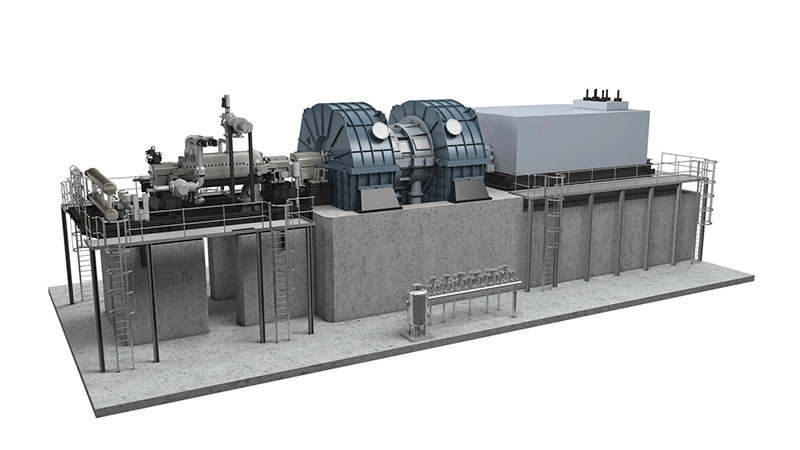

The SST-800 is a single casing steam turbine with center steam admission and reverse steam flow inner casing, designed for a direct coupled generator or mechanical drive.

The highly customized turbine provides for an outstanding efficiency, fast start-up times and high reliability and availability. It supports all requirements for economical installation and operation in combination with highest flexibility for complex industrial processes. A double or even multicasing solution can also be provided.

The SST-800 steam turbine can be used for both condensing and back-pressure applications. Turbine auxiliary systems are also designed as pre-engineered modules covering the complete range of turbine sizes.

The turbine can be arranged on a foundation or as a package (includung oil system and on a base frame). The SST-800 steam turbine design is in accordance with DIN or API standards.

Technical Data:

Typical Applications:

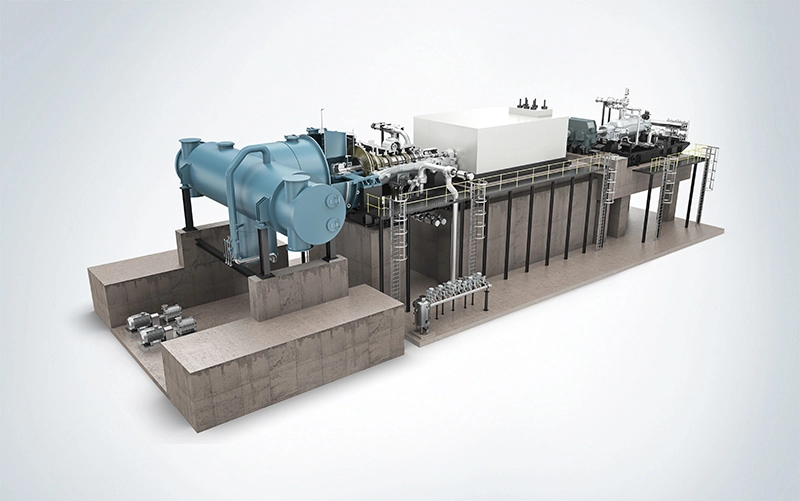

SST-700/900

The SST-700 / 900 is a standard turbine solution with short delivery time due to its fixed pre-engineered design. Predefined modules enable a short manufacturing period, cost-efficient material supply and a fast ex-works delivery.

The straight flow turbine solution with power output of up to 250 MW consists of a geared high-pressure steam turbine (backpressure), an intermediate / low-pressure steam turbine (condensing), both driving a generator installed in between.

The dual casing reheat turbine configuration with inner casing is a competitive and optimized product for combined cycle power plants and concentrated solar power plants.

Technical Data:

Typical Applications:

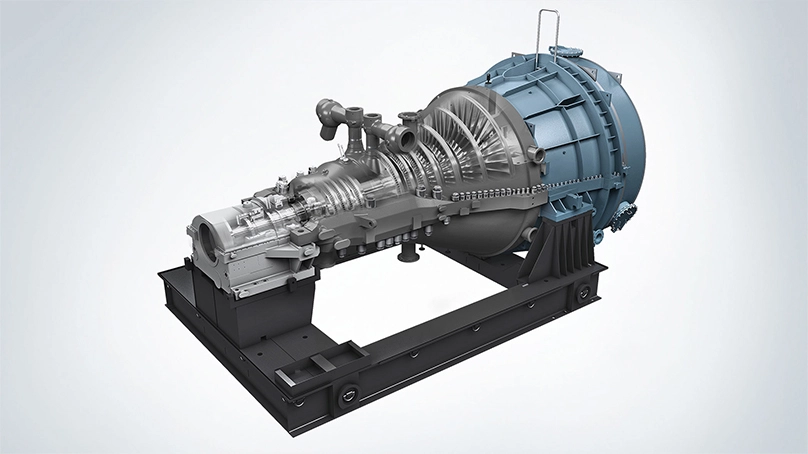

SST-600

We deliver a standard steam turbine generator set including the SST-600 (with or without gearbox), a generator, oil system, piping and instrumentation and the control system. The standard package can be extended to include a condenser, condensing plant or pre-heating system. The SST-600 with its reliable and flexible design is available with axial or radial exhaust.

Mechanical Drive

The SST-600 is also an efficient and economic mechanical drive. Since the 1970s, hundreds of projects have been successfully implemented all over the world using the SST-600 to directly drive everything from the smallest boiler feedwater pump just as reliably as the largest compressor even in the most complex processes. The SST-600 complies with regulations including the API standard.

Technical Data:

Typical Applications:

SST-500

The SST-500 is a single casing, double exhaust flow steam turbine, which can be used as an entire drive or as the lowpressure module of a multiple-casing turboset, directly driven or geared. This turbine, with its capacity to operate over a wide range of speed and power, is ideal for large steam volume flows. Steam flows into the turbine via two tangential inlets to equalize thermal loading and blade stress.

Emergency stop valves and control valves are installed in the steam inlet pipes. The steam flows tangentially into the inner casing and then axially to both exhausts. The customized design of the steam path allows exact adjustment to surpass general physical limitations of the last stage blades. Double-end drive is available, if required, e.g. for booster pump drive

Technical Data:

Typical Applications:

Get Free Solution

We provide medium and long-term solutions to the problems of biomass waste, transforming waste into energy at no environmental cost and making it economically viable and at the same time compatible with the international environmental regulations and standards

Get More Product Information For Free